Grey Jeweler’s Forceps: Precision and Versatility in Surgical and Industrial Applications

Grey Jeweler’s Forceps: Precision and Versatility in Surgical and Industrial Applications

Blog Article

Grey Jeweler’s Forceps are finely crafted precision instruments used in both medical and industrial applications. These forceps are characterized by their slim, pointed tips, ergonomic design, and exceptional control, making them an invaluable tool for handling delicate and intricate materials. Originally designed for use in the grey jewelry industry, these forceps have found widespread adoption in surgical, laboratory, and electronic settings due to their superior craftsmanship and precision.

Design and Features

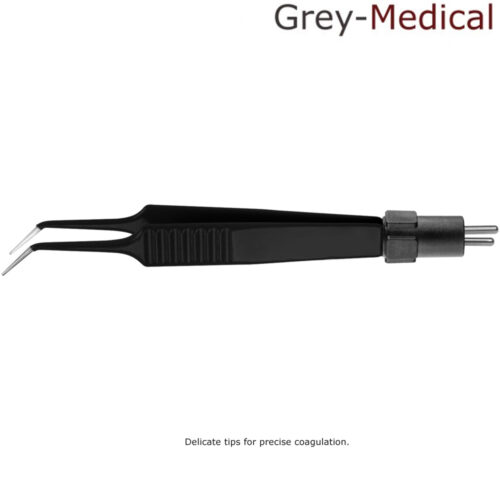

Grey Jeweler’s Forceps are renowned for their meticulous design. Made from high-quality materials, such as stainless steel or titanium, these forceps are resistant to corrosion and wear, ensuring longevity and reliability. Their lightweight construction minimizes hand fatigue during prolonged use, while the fine, pointed tips allow for precise manipulation of small objects.

The tips of the forceps are typically serrated to provide a secure grip on even the most delicate materials, such as surgical sutures, fine wires, or gemstones. The handles are designed to be ergonomic, offering comfort and control for the user. Some variations include anti-magnetic or non-reflective coatings, enhancing their utility in specialized environments such as electronics or operating rooms.

Applications in Surgical Settings

In the medical field, Grey Jeweler’s Forceps are indispensable for microsurgery and delicate procedures requiring exceptional precision. Surgeons often use these forceps in ophthalmic surgeries, neuro surgeries, or vascular procedures where handling fine sutures or tissues is critical. Their slender, pointed tips allow for access to confined areas without causing unnecessary trauma to surrounding tissues.

In plastic and reconstructive surgery, these forceps are used for tasks such as grasping small grafts, holding fine sutures, or aligning delicate tissue structures. Their precision makes them an ideal choice for surgeries that demand the highest level of accuracy and control.

Use in Industrial and Laboratory Settings

Beyond medical applications, Grey Jeweler’s Forceps are widely used in industries such as jewelry making, watch repair, and electronics. Their ability to handle minute components, such as gemstones, screws, or microchips, with precision makes them a trusted tool among jewelers and technicians. In laboratories, these forceps are employed for handling delicate specimens, assembling fine equipment, or performing intricate experiments.

Their versatility extends to hobbyists and craftsmen who rely on these forceps for detailed tasks, such as model building, assembling intricate mechanisms, or repairing fine instruments.

Variations and Customization

Grey Jeweler’s Forceps come in various lengths, tip styles, and materials to cater to different needs. Variations include straight or curved tips, serrated or smooth jaws, and anti-magnetic or corrosion-resistant finishes. For surgical use, some models feature insulated handles to prevent electrical conduction during electrosurgical procedures. Custom laser marking is also available to ensure easy identification and organization in busy environments.

Care and Maintenance

Proper care and maintenance are essential to preserve the precision and functionality of Grey Jeweler’s Forceps. Regular cleaning and sterilization are necessary for medical applications, while industrial users should clean the forceps to prevent buildup of debris. Periodic inspection for wear and tear, as well as careful handling to avoid damage to the fine tips, ensures the longevity of the instrument.

Conclusion

Grey Jeweler’s Forceps are a testament to the importance of precision tools in both medical and industrial settings. Their finely tuned design, versatility, and durability make them an indispensable instrument for handling delicate materials and performing intricate tasks. Whether in a surgeon’s hand, a jeweler’s workshop, or an electronics laboratory, these forceps deliver unmatched performance and reliability, underscoring their value in diverse applications. Report this page